As a handful of journalists snapped pictures, poked at touch screens, and flipped open the charging ports on the trio of preproduction (Betas, they call them) Model S's parked outside the Tesla (ex-NUMMI) factory in Fremont, California, I had one solitary thought:

This is it.

The future of the 100-percent battery-powered electric automobile could very well pivot on what's in front of me. If you're one of those who's enchanted by an Tomorrowland-like, electric-car future, you'd better hope the Tesla Model S succeeds. If you're among its detractors, well, now's the time to start pressing pins into your knitted Model S doll. But no matter what, the Model S is going to be a very difficult electric car to dismiss.

Because it's a real car. Let me explain that statement. Remember GM's EV1? It was a brilliant car...that was drastically undermined by its 1990's battery technology (I actually pushed one down a street when its battery died). In most people's eyes, it was simply not a "real car." Battery technology hasn't been nearly as problematic for the more recent Tesla Roadster -- lithium-ion chemistry allows it to travel 200-plus miles between charges and be fast as heck -- but it regularly gets dismissed as too expensive to be a "real car." And ironically, the new Nissan Leaf -- neither expensive nor archaic -- seems to have come full circle, finding itself batted aside by some critics because of the EV1's old Achilles heel: limited range. (Roughly 75 mile range in this case.) Too little to be a "real car."

None of this can be said about the Model S. In its base version, it'll cost $57,400 (add about $1950 for destination) and be eligible for a federal $7500 tax credit (and depending on where you live, additional local ones). Here in California, for instance, that means the price will be about $49,350 (after including our state $2500 tax credit as well). Not cheap, but there's a whole lot of vastly less interesting sedans out there that regularly sell for $49,350. (Don't make me name names.) Moreover, unlike the Volt and Leaf, the Model S's charger is part of the deal, built right into car.

For that sum you'll get the standard battery pack capable of a 160-mile range, a crummy distance in conventional gas car terms. But I'd reckon that 160 miles (more than twice the Leaf's) would eliminate the daily-driving range phobia I've occasionally felt behind the wheel of the otherwise likeable little Nissan. And to get off on the right foot, the kickoff 1000 'Signature' Model S's will all carry the big, optional 300-mile range battery, which does tack a fat $20K onto the price. (The intermediate choice is a 230-mile range battery pegged at an additional $10,000). A little pencil work suggests Tesla is consequently charging $504 per kW-hr of energy storage -- which is actually an attractive price at the moment.

Plugged into high-amperage, 240-volt juice, the Model S recharges at a massive rate of 62 miles per hour -- meaning 2.6 hours for the 160-mile battery, about five hours for the 300-mile version (120-volt charging should be regarded as an emergency measure). Fast charging can replenish 80 % of the battery's capacity in 45 minutes. A problem Tesla has faced as a pioneer is that it's constantly a step ahead of international standards. With the Roadster, Tesla had to create its own version of what's now called a level 2 charging receptacle before an SAE standard was established; when the J1772 plug appeared, it had to create an adaptor. It's happening again as Tesla now has to come up with its own integrated levels 1, 2, and 3 (direct current, 400-plus volts) receptacle before the SAE version was ready. (The Leaf's optional level 3 port is separate from its J1772 standard, and an awkward solution). Tesla defends its proprietary plug as better than trying to chase independent standards employed in Europe, the U.S., and Asia. Consequently, if you want to plug a Model S into, say, a ChargePoint station in the U.S., you'll first need to attach an adapter.

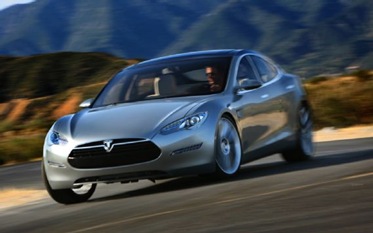

While the Tesla Roadster has been unfairly labeled an electric Lotus (derived, perhaps), that won't happen with the Model S as virtually every spec of it is original. Overall, its presence struck me as something like a more organic Audi A7, meaning it's a stylishly windswept four-door fastback with a clear accent on performance. Parked side-by-side with the Audi, they're just about the same length, with the Tesla measuring an inch taller and wider. And like the Audi, the Model S is almost entirely aluminum, with bolding via adhesives, rivets, and welds, depending on the circumstance.

At this moment, I'm one of Earth's few inhabitants to have ridden in both Fisker's Karma and Tesla's Model S (at least in this pre-production guise), and maybe the most startling difference between them is space efficiency. The Karma's vastly smaller, 20 kW-hr battery runs down the car's spine, dividing the interior so utterly that there's not only room for just two in back, but I'd advise them to be 12 years old. Its trunk? Don't play golf. However, the Model S's battery -- despite being more than four times bigger -- is sort of like a 3- or 4-inch-thick sheet of plywood bolted under the car (and said to be removable in minutes). As the rear-mounted motor and reduction gears are quite small, the result is astonishing.

Like a big Porsche Cayman, there's trunks both front (8.1 cubic feet) and rear (a giant 28.7, rising to 58.1 with the aft seats collapsed). There's room for five, offering more space than the A7 in just about every dimension except rear headroom (the same) and rear shoulder room (0.9 inch less). What with the sloping roofline -- as well as mechanisms needed for the large retractable glass panoramic roof (standard equipment) -- I had to watch my noggin getting in and out (I'm 6 foot 1 inch), but it's not much different than the A7. On the other hand, there's a thoughtful cut-out for feet beneath the front seat bottom, something that's amazingly neglected in too many cars. And oh, about those two little optional rear-facing seats (seats 6 and 7)...

In fact, they're removable, five-belt child affairs, so their occupants' size is literally restricted by law. I actually climbed back there, but being considerably past child-seat age (when I was a kid, I used to stand on a front bench seat, for heaven's sake) all I could judge is that they're definitely close to the rear bumper. But no more so than the third row of many minivans. Would I put a kid there? Well, the seats do provide some flexibility in a pinch...and that's about it.

A funny thing about the Model S is that I suspect its biggest talking point might not be its range and recharge times, but the 17-inch, high-res, full-color display in the middle of the dash. I don't often mutter "Cool..." anymore, but mutter it I did as I began to tap my way through its configurations. Like the iPad? This is an iPad on steroids, offering access to the Web, climate controls, and a Google maps navigation presentation that is simply terrific. It's so good (judging from the prototype screen) that it might be a considerable driver distraction. (It isn't clear how web connectivity while driving will be handled.) However, I'd suggest that its extraordinary size could actually become a safety benefit if what's displayed on the screen was greatly enlarged so it's easy to read and touch-sensitive taps don't need to be well-targeted. This might be the first time a display's size and high-quality graphics actually add to the attractively modern interior design. Of the three cars available to us, one was described as representative of fit and finish, and while it was very nicely, and expensively, executed, it's really impossible to judge any of this until we see a production -- rather than a hand-built -- example.

My ride in the Model S was a brief circuit around the factory grounds and the banked corners that punctuate the ends of the tiny test track left over from the NUMMI days. But I was quickly surprised by a couple of things. The car's acceleration -- claimed to be 5.6 seconds to 60 mph -- is a continuous press-the-seat-back surge that only a single-speed, big electric motor can provide. (Top speed is 130 mph, and a sub-5-second, 320-mile range has been mentioned for a sport variant.) Aided by liquid cooling, the motor generates 306 hp at 7000 rpm and 362 lb-ft of torque between 6500-10,000 rpm (redline is 14k!). Interestingly, while the motor is quiet, its growly roar is a very different acoustic signature than the frenetic whine in the Roadster. Tesla claims that's just how it sounds, and no acoustic modifications have been attempted. Bumps were nicely absorbed amid muted tire-impact noises, and the lateral grip seemed considerable for a car over 4000 pounds. That low battery location and compact powertrain are very helpful.

THE FACTORY

Selfishly, I'll admit that during our tour of the ex-NUMMI digs, I was thinking it's sure nice to be taking a tour of a car factory without being jet lagged. Tesla's digs are 350 miles north of our spacious cubicles in El Segundo. Not 5000 miles east or 7000 miles east. What a novelty.

Of course, what's much more important here is the pundit-defying reality of all the shiny new industrial decoration surrounding me. For all I know, Tesla may suddenly go all Solyndra on us. But at this particular time-stamp in history, I'm standing in the middle of a genuine electric car factory.

There's the smell of fresh paint. Gleaming painted floors. Gigantic (I mean "Transformers"-scale) stamping machines that were shipped from Detroit in pieces, requiring numerous trucks and train cars to transport (a 20-foot-deep concrete-lined subterranean pit was created to support them). And everywhere you look are brigades of brand-new robots busily showing off their dexterity by swiveling their wrists and doing a pantomime of handing body parts to one another. Eerily, they're actually handling nothing but pieces of air, as the stamping dies needed to make those parts won't be showing up a few more weeks, but they're practicing nonetheless. Curiously, not that much of the pre-existing machinery is being used -- at least yet.

I've listened to endless auto industry wags dismissively bellow that it's one thing to make some high-priced electric sports cars by piggybacking on low-production Lotus know-how. But real car-making, they harrumph, is beyond those helpless, Silicon Valley know-nothings. Search engines and social networks are not automobiles. I'm wondering if it isn't a strength.

For instance, one unusual twist is the degree to which automated die changes are part of the production process. Those giant stamping machines are frightfully expensive, so it's cheaper to robotically switch dies in and out of them. Another is the plant's micro re-envisioning of a Rouge River-esque, soup-to-nuts manufacturing strategy. Counter to the conventional wisdom to subcontract just about everything -- with car companies doing not much more than final assembly -- nearly the entire Model S will be created onsite. The motors will be wound in one place, the batteries assembled nearby, the stamping happens over there. There's an injection molding center with sparkling new presses, likewise a paint line that's almost entirely robotic. Even the leather works (a separate company) will be co-located on site. Gilbert Passin, VP of Manufacturing, explained that given the gigantic sprawl of the virtually free facility (Tesla paid $47 million dollars for the property and $18 million for the existing machinery -- after which Toyota invested $50 million in Tesla), and how remote California is from the suppliers surrounding Detroit, it just make sense. In its prime, NUMMI produced about 500,000 Toyota and GM cars. Right now, Tesla is employing somewhere between 15 to 20 percent of the main building (the rest is simply mothballed). Indeed, being that the cars are electric and can be driven indoors, the final evaluation track -- speed bumps, road ripples, etc -- is within the same massive space as the final assembly line. Why not? There's room.

Despite its innovative nature, Tesla's key positions are all populated by guys who have a clue: CTO J.B. Straubel co-founded the aerospace company Volacom; the Model S's designer is Franz Von Holzhausen, previously Director of Design at Mazda and creator of the Saturn Solstice and Sky while at GM; the chief engineer is Peter Rawlinson, who did the same for Lotus' Advanced Engineering, previously worked on Jaguars and BMWs, and is an expert in aluminum construction; and there's Passin, who lords over the manufacturing facility and was previously general manager of production engineering for Toyota North America. Even the guys responsible for the German-made presses are Germans, hired directly from the factory for their knowhow. (I'm also told there's also a guy named Elon Musk who's somehow involved.)

And all of this expertise, money, property, buildings, robots, and hopes is now focused on a batch (well under 100) of Beta 2 Model S's for final, production-line evaluation. After that, the plan is to build about 5000 cars in 2012, with the numbers ramping up to 20K per year after that. Deliveries are scheduled to begin in the middle of next year. And at that point we might finally see if the Model S is the car that makes the electric automobile a force -- or kills it forever.